Insulating Your Basement Ceiling: A Comprehensive Guide

Insulating a basement ceiling is a crucial step in improving home energy efficiency, enhancing comfort, and potentially reducing utility bills. This undertaking can significantly impact the overall temperature regulation within a home, mitigating heat loss during colder months and preventing the buildup of excess heat during warmer periods. This guide provides a detailed overview of the process, materials, and considerations involved in effectively insulating a basement ceiling.

A basement ceiling acts as a thermal barrier between the basement and the living areas above. Without proper insulation, heat can easily escape from the upper floors into the basement, forcing the heating system to work harder and consume more energy. Conversely, in the summer, heat from the basement can rise into the living areas, straining the air conditioning system. Insulating the basement ceiling helps to maintain a consistent temperature on both levels, creating a more comfortable and energy-efficient environment.

Before embarking on the insulation project, it is essential to assess the basement environment. High moisture levels are a common concern in basements and can compromise the effectiveness of insulation. Addressing any existing moisture issues, such as leaks or condensation, is paramount. Proper ventilation can also help to reduce humidity levels. Ignoring moisture problems before insulating can lead to mold growth, reduced insulation performance, and potential structural damage.

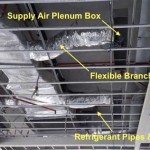

Planning is another essential step. This includes determining the appropriate type of insulation based on factors such as budget, desired R-value (resistance to heat flow), and ease of installation. Measuring the ceiling area accurately is critical for calculating the required amount of insulation material. It is also important to consider any obstructions, such as pipes, wiring, and ductwork, which may require specific insulation techniques or materials.

Selecting the Right Insulation Material

Various insulation materials are suitable for basement ceiling applications, each with its own advantages and disadvantages. Choosing the appropriate material depends on factors such as budget, desired R-value, moisture resistance, and ease of installation.

Fiberglass batt insulation is a common and relatively inexpensive option. It is available in various R-values and thicknesses. Fiberglass batts are easy to install between joists but require careful handling to avoid skin and respiratory irritation. It's important to ensure proper sealing to prevent air leaks, which can reduce its effectiveness. Also, fiberglass is susceptible to moisture damage, so it's crucial to address any basement moisture problems before installation.

Rigid foam board insulation, such as extruded polystyrene (XPS) or polyisocyanurate (polyiso), offers higher R-values per inch compared to fiberglass. It is more resistant to moisture and can provide an air barrier, further enhancing its insulating properties. Rigid foam boards are typically attached directly to the basement ceiling using adhesive or mechanical fasteners. Cutting and fitting the boards around obstructions can be time-consuming, but the increased energy efficiency and moisture resistance make it a worthwhile option, particularly in damp basements.

Spray foam insulation offers excellent thermal performance and air sealing capabilities. It expands to fill gaps and crevices, creating a tight barrier against heat loss and air infiltration. There are two main types of spray foam: open-cell and closed-cell. Closed-cell foam has a higher R-value and is more resistant to moisture, making it suitable for basements. However, spray foam insulation is generally more expensive than fiberglass or rigid foam board and requires professional installation. It's also essential to ensure proper ventilation during and after installation due to the potential release of volatile organic compounds (VOCs).

Mineral wool insulation, made from recycled glass or stone, offers good thermal performance and fire resistance. It is also relatively resistant to moisture and mold growth. Mineral wool batts are installed similarly to fiberglass batts, but they are denser and easier to work with. Mineral wool can be a good option for homeowners looking for a more environmentally friendly and fire-resistant insulation material.

Reflective insulation, such as radiant barrier foil, reflects radiant heat rather than absorbing it. It is most effective in climates with high solar radiation. Reflective insulation is typically installed with an air space between the foil and the ceiling, which can be challenging in some basement configurations. While it can help reduce heat gain in the summer, its effectiveness in cold climates is limited.

Preparing the Basement Ceiling for Insulation

Proper preparation is essential for ensuring successful insulation installation. This includes cleaning the ceiling, addressing any existing issues, and taking necessary safety precautions.

Before starting the insulation process, thoroughly clean the basement ceiling. Remove any dust, debris, or cobwebs that may interfere with the adhesion of insulation materials or create a breeding ground for mold. A vacuum cleaner with a brush attachment can be used to clean between joists and around pipes and wiring. If there is any evidence of mold growth, it should be addressed with a mold-killing solution before proceeding.

Inspect the basement ceiling for any existing problems, such as leaks, cracks, or structural damage. Repairing these issues before insulating is crucial to prevent future problems. Leaks should be patched, cracks should be filled, and any structural damage should be addressed by a qualified professional. Ignoring these problems can compromise the effectiveness of the insulation and lead to more significant issues down the road.

Identify and address any wiring or plumbing issues before installing insulation. Ensure that all electrical wiring is properly insulated and that there are no exposed wires. If there are any plumbing leaks, repair them before proceeding. Consider insulating any exposed pipes to prevent condensation and potential freezing during cold weather. Secure any loose wires or pipes to the joists to prevent them from interfering with the insulation.

Safety is paramount when working with insulation materials. Wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a dust mask or respirator. Insulation materials can cause skin and respiratory irritation, so it's essential to protect yourself. Work in a well-ventilated area to minimize exposure to dust and fibers. If using spray foam insulation, follow the manufacturer's instructions carefully and ensure proper ventilation.

Installation Techniques and Considerations

The specific installation techniques will vary depending on the type of insulation material chosen. However, some general principles apply to all basement ceiling insulation projects.

When installing fiberglass batts, cut the batts to fit snugly between the joists. Ensure that the batts are properly aligned and that there are no gaps or voids. If the batts have a paper or foil facing, install the facing towards the heated side of the ceiling (i.e., towards the living area above). Staple the facing to the joists to secure the batts in place. Be careful not to compress the batts, as this can reduce their R-value. Avoid leaving any empty spaces around pipes or wiring; instead, carefully cut and fit the batts around these obstructions.

When installing rigid foam board, measure and cut the boards to fit snugly against the basement ceiling. Use a construction adhesive or mechanical fasteners to attach the boards to the ceiling. Ensure that the boards are properly aligned and that there are no gaps or voids. Seal the seams between the boards with foil tape or caulk to prevent air leakage. Be aware that some rigid foam boards are flammable and should be covered with a fire-resistant material, such as drywall, in accordance with local building codes.

If using spray foam insulation, hire a qualified professional to ensure proper installation. The applicator will spray the foam onto the basement ceiling, filling all gaps and crevices. The foam will expand and harden, creating a tight seal. Ensure that the area is properly ventilated during and after installation to minimize exposure to VOCs. Allow the foam to cure completely before finishing the ceiling.

When insulating around pipes and wiring, be careful not to damage these utilities. Wrap pipes with insulation sleeves or foam tape to prevent condensation and freezing. Use caution when cutting insulation around wiring to avoid damaging the wires. Secure any loose wires or pipes to the joists to prevent them from interfering with the insulation.

Maintain proper ventilation in the basement after insulating. Insulating the basement ceiling can reduce air flow and potentially increase humidity levels. Consider installing a dehumidifier to control moisture levels and prevent mold growth. Ensure that any existing ventilation systems are functioning properly. Regular monitoring of humidity levels is recommended to identify and address any potential moisture problems.

A Guide On Basement Ceiling Insulation

How To Insulate And Seal Rim Joists

What Is Basement Ceiling Insulation And It Worth

Should I Insulate My Basement Ceiling And Walls Aire Serv

Ceiling Insulation Your Complete Guide 2025

How To Insulate Your Basement A Complete Guide Lux Construction

Ceiling Insulation Your Complete Guide 2025

Basement Ceiling Insulation Types Costs Pros Cons

Basement Ceiling Insulation Types Costs Pros Cons

Soundproofing Ceilings How To Soundproof A Ceiling

Related Posts