How To Install HVAC Duct In Ceiling

Installing HVAC ductwork in a ceiling requires careful planning and execution to ensure efficient airflow and system performance. This article outlines the process, providing a comprehensive guide for successful installation.

Planning and Preparation

Before beginning any physical installation, thorough planning is essential. This includes determining the appropriate duct size based on the HVAC system's requirements and the layout of the space being served. Accurate measurements of the ceiling cavity and the planned duct runs are crucial. Consideration should also be given to accessibility for future maintenance.

Choosing the correct duct material is another critical step. Options include flexible duct, rigid metal duct, and fiberglass duct board. Each material has its advantages and disadvantages regarding cost, ease of installation, and airflow efficiency. Flexible duct is often preferred for its maneuverability, while rigid duct offers superior airflow characteristics.

Gathering the necessary tools and materials beforehand streamlines the installation process. Essential tools include a measuring tape, tin snips, duct sealant, screws, drill, and safety equipment such as gloves and eye protection. Having all necessary components readily available prevents delays and ensures a smooth workflow.

Installing the Main Trunk Line

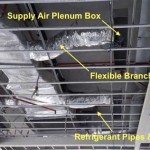

The main trunk line serves as the primary artery of the HVAC system, distributing conditioned air throughout the space. It is typically installed first, running from the air handler or furnace to the various branch ducts. Securely supporting the trunk line is vital to prevent sagging and ensure proper airflow. Hangers or straps should be spaced appropriately according to the duct material and size.

Connecting the main trunk line to the air handler or furnace requires a precise fit and airtight seal. Use appropriate connectors and sealant to prevent air leakage, which can significantly reduce system efficiency. Carefully follow the manufacturer's instructions for connecting the ductwork to the unit.

Running Branch Ducts

Branch ducts extend from the main trunk line to deliver conditioned air to individual rooms or zones. These ducts are typically smaller in diameter than the trunk line and require careful routing to ensure adequate airflow to each location. Avoid sharp bends and kinks in the ductwork, as these can restrict airflow and increase noise levels.

Insulating the ductwork is essential to minimize heat loss or gain and improve energy efficiency. Insulation also helps to reduce condensation and noise transmission. Wrap the ductwork with insulation material, securing it with tape or ties, ensuring complete coverage.

Connecting Branch Ducts to Registers and Grilles

Registers and grilles are the final points of air delivery into the conditioned space. Connecting the branch ducts to these components requires careful alignment and sealing. Use appropriate connectors and sealant to ensure an airtight connection and prevent air leakage. Ensure that registers and grilles are positioned correctly to provide optimal airflow distribution within the room.

Sealing and Testing

Once the ductwork is completely installed, thorough sealing is essential to maximize system efficiency and prevent air leakage. Apply duct sealant to all joints, seams, and connections, paying close attention to areas where leaks are likely to occur. Allow the sealant to dry completely before testing the system.

Testing the system after installation is crucial to verify proper airflow and identify any leaks. A common method involves using a duct blaster, a specialized fan that pressurizes the duct system. This allows technicians to pinpoint leaks by observing pressure changes or using smoke pencils to detect escaping air. Addressing any leaks promptly ensures optimal system performance and energy efficiency.

Safety Considerations

Working in ceiling spaces presents inherent safety risks, and precautions should be taken throughout the installation process. Wear appropriate safety equipment, including gloves, eye protection, and a dust mask. Be aware of electrical wiring and other potential hazards in the ceiling cavity. Use caution when working on ladders or scaffolding, and ensure proper stability before starting any work.

Ducts In Dropped Ceilings Building America Solution Center

How To Frame Around Hvac Ducts Or Pipes In A Basement Easiest Method

How To Install Ductwork In A Basement Diy Finished Renovation

Incredible Exposed Duct Work Installation Finishing

Flex Ducts Are Yours Installed Properly Kalos Services

Hvac Sheet Metal Basics 3 Methods For Hanging Duct

Ducts In Dropped Ceilings Building America Solution Center

Hvac Ductwork Air Duct Types Working Problems Installation Austin Area Conditioning And Heating G S Mechanical

6 Tips For Installing Ductwork In The Attic

Keep Out One Place Never To Put Hvac System Ducts Energy Vanguard

Related Posts